Electrical Systems in Automobile and Industrial: A Comprehensive Guide for Auto Repair

In today’s modern world, electrical systems play a pivotal role in the functioning of both automobiles and industrial machinery. From powering essential components to ensuring smooth operations, these systems are at the heart of technological advancements. Consider the case of an automobile; imagine being on a long road trip when suddenly, the dashboard lights start flickering, and the engine stalls. This unfortunate scenario demonstrates how crucial it is for individuals to have a comprehensive understanding of electrical systems in order to diagnose and repair such issues effectively.

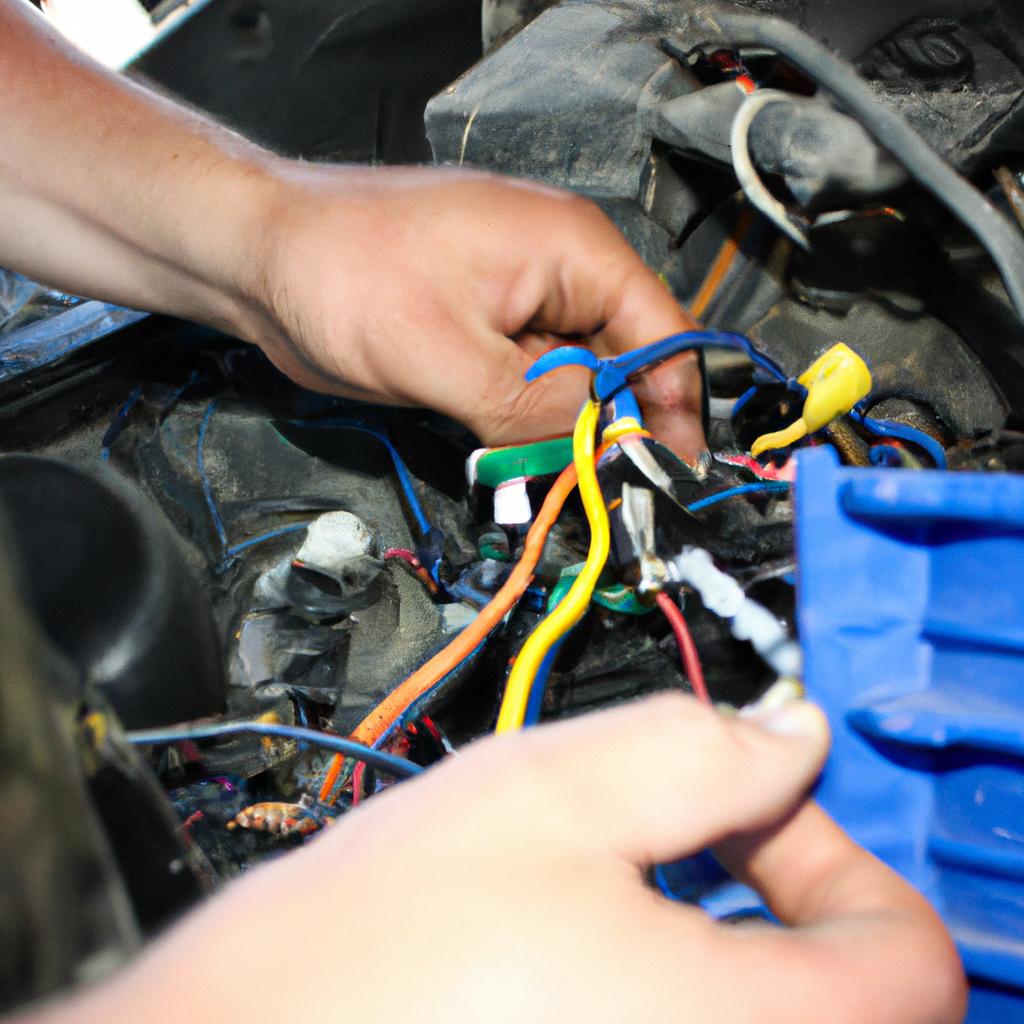

Understanding electrical systems in automobiles and industrial settings requires knowledge encompassing various aspects, including wiring diagrams, circuitry analysis, and component identification. The complexity of these systems necessitates a thorough comprehension not only of their fundamental principles but also of troubleshooting techniques. Furthermore, as technology continues to evolve rapidly, staying up-to-date with new developments in electrical engineering becomes imperative for auto repair professionals seeking to provide efficient solutions for customers’ needs.

Thus, this comprehensive guide aims to explore the intricacies surrounding electrical systems in both automotive and industrial contexts. By delving into topics such as voltage regulation, battery management, sensor integration, and fault diagnosis methods relevant to these domains, readers will gain valuable insights into maintaining optimal performance levels while minimizing downtime caused by electrical malfunctions. Through an academic approach, this guide will provide a solid foundation of knowledge for individuals looking to understand and troubleshoot electrical systems in automobiles and industrial machinery.

To begin, the guide will cover the basic principles of electricity, including voltage, current, resistance, and power. It will explain how these concepts relate to electrical systems and provide a framework for understanding more complex topics.

Next, the guide will delve into wiring diagrams and circuitry analysis. It will explain how to interpret these diagrams and identify various components within an electrical system. Understanding the layout of a system is crucial for diagnosing issues and making repairs effectively.

The guide will also explore various components commonly found in electrical systems, such as batteries, alternators, starters, motors, sensors, and relays. It will explain their functions and how they interact with other components to ensure proper operation.

Voltage regulation is another critical aspect that will be covered in the guide. It will explain different methods of regulating voltage within an electrical system to prevent damage to sensitive components and ensure stable operation.

Battery management is also essential for maintaining optimal performance levels. The guide will discuss techniques for testing battery health, charging procedures, and troubleshooting common battery-related issues.

Sensor integration plays a vital role in modern electrical systems. The guide will explore different types of sensors used in automobiles and industrial machinery and explain their importance in providing accurate data for system control and monitoring.

Lastly, the guide will introduce various fault diagnosis methods that can be employed when troubleshooting electrical issues. It will cover techniques such as continuity testing, voltage measurements, component isolation, and computer diagnostics.

By providing comprehensive coverage of these topics, this guide aims to equip readers with the necessary knowledge to understand electrical systems in automobiles and industrial settings fully. Whether you are a professional working in auto repair or an enthusiast seeking to enhance your understanding of electrical systems’ intricacies, this guide offers valuable insights that can help you diagnose problems accurately and implement effective solutions.

Understanding Electrical Systems in Vehicles

Imagine driving your car on a busy highway when suddenly, the engine stops working. You try to start it again, but nothing happens. What could be the problem? In many cases, this frustrating situation can be attributed to issues within the electrical system of the vehicle. Understanding how these systems work is essential for any auto repair technician or enthusiast.

Main Body:

To begin comprehending vehicle electrical systems, it is important to grasp their fundamental function. The primary purpose of an automobile’s electrical system is to generate and distribute electrical power throughout the vehicle. This power supply enables various components such as lights, starter motors, ignition systems, and electronic control units (ECUs) to operate effectively. By understanding this concept, one gains insight into diagnosing and resolving problems related to faulty wiring, loose connections, or malfunctioning components.

Now let us consider some key features that make automotive electrical systems fascinating:

- Reliance on Alternating Current (AC): Unlike common household appliances which predominantly use direct current (DC), vehicles primarily rely on alternating current for their electrical needs. This characteristic necessitates specialized components designed specifically for AC circuits.

- Sophisticated Control Modules: Modern cars incorporate advanced technologies like microcontrollers and digital signal processors to regulate various functions within different subsystems. These control modules ensure optimal performance while enhancing safety measures.

- Integration with Mechanical Systems: Vehicle electrical systems are intricately connected with mechanical subsystems such as engines and transmissions. They enable coordination between diverse parts by transmitting signals through sensors and actuators.

- Emphasis on Safety Measures: Automobile manufacturers prioritize safety by incorporating various protective mechanisms in their electrical designs. Examples include circuit breakers, fuses, grounding techniques, and insulation materials that safeguard against overheating or short-circuits.

In addition to these intriguing aspects of automotive electrical systems, we can also represent their complexity using a table:

| Component | Function | Example |

|---|---|---|

| Battery | Provides electrical energy | Lead-acid or lithium-ion batteries |

| Alternator | Generates electricity | Converts mechanical power to AC |

| Starter motor | Initiates engine combustion | Cranks the engine for ignition |

| Ignition system | Sparks fuel-air mixture | Distributes high-voltage sparks |

Understanding the intricacies of vehicle electrical systems is crucial in diagnosing and resolving issues that may arise during auto repair. By comprehending their fundamental function, relying on alternating current, integrating with mechanical subsystems, and emphasizing safety measures, technicians can effectively diagnose problems and ensure optimal performance.

Now that we have established a foundation for understanding vehicle electrical systems, let us delve into the key components that constitute these intricate networks.

Key Components of Vehicle Electrical Systems

Now that we have explored the basics of electrical systems in vehicles, let us delve deeper into the key components that make up these intricate systems. To illustrate their importance, consider a scenario where a car’s headlights suddenly stop working while driving at night. This situation not only poses a safety risk but also emphasizes the critical role of various components within the vehicle’s electrical system.

The electrical system in automobiles comprises several essential elements:

- Battery: The primary power source for the entire electrical system, providing electricity to start the engine and powering other electrical components when the engine is off.

- Alternator: Responsible for generating electricity by converting mechanical energy from the engine into electrical energy, which charges the battery and supplies power to all electrical devices.

- Starter Motor: Engages with and turns over the internal combustion engine, initiating its operation.

- Ignition System: Facilitates spark generation necessary for igniting the fuel-air mixture in an internal combustion engine.

Consider this hypothetical case study to better understand how these components work together:

Imagine you are driving down a dimly lit road when your car suddenly loses power. With no functioning headlights or dashboard lights, panic ensues as visibility decreases rapidly. Upon closer inspection, it is discovered that a faulty alternator has caused complete depletion of the battery’s charge. In this instance, understanding each component’s function would help identify and rectify issues promptly.

To further grasp these concepts visually, here is an emotional bullet point list showcasing some common problems related to vehicle electrical systems:

- Flickering headlights

- Dead battery

- Malfunctioning power windows

- Unresponsive radio or audio system

Additionally, refer to this informative table (markdown format) highlighting key characteristics of different electrical system components:

| Component | Function | Common Issues |

|---|---|---|

| Battery | Provides initial power | Acid leakage |

| Alternator | Generates electricity | Bearing failure |

| Starter Motor | Engages the engine | Worn-out brushes |

| Ignition System | Facilitates spark ignition | Faulty spark plugs |

In summary, comprehending the various components within a vehicle’s electrical system is crucial for both auto repair professionals and car owners. By familiarizing ourselves with these elements and their functions, we can better diagnose issues and ensure optimal performance of our vehicles.

Moving forward, let us now explore common electrical issues in automobiles and industrial equipment to further enhance our understanding of these intricate systems.

Safety Measures for Working with Electrical Systems

Imagine a scenario where an industrial facility experiences frequent power outages, resulting in production delays and loss of revenue. In the automotive industry, consider a situation where a car’s electrical system malfunctions, causing issues with critical components such as headlights or engine ignition. These examples highlight the importance of understanding common electrical issues that can arise in both automobiles and industrial equipment.

To effectively troubleshoot and resolve these problems, it is crucial to be aware of the most prevalent electrical issues encountered. Here are some frequently observed challenges:

- Battery Problems: A weak battery or faulty charging system can lead to difficulties starting the vehicle or machinery.

- Faulty Wiring Connections: Loose connections or damaged wiring can result in intermittent failures of various electrical components.

- Blown Fuses: Overloading circuits or short circuits may cause fuses to blow, leading to the loss of specific functions within the system.

- Grounding Issues: Insufficient grounding can interfere with proper functioning of electrical systems, potentially causing erratic behavior or complete failure.

Addressing these concerns requires a systematic approach based on sound knowledge and expertise. To assist in this process, we have provided a table below outlining potential causes and symptoms for each issue mentioned above:

| Common Issue | Potential Causes | Symptoms |

|---|---|---|

| Battery Problems | Aging battery | Difficulty starting |

| Faulty alternator | Dimming lights while driving | |

| Faulty Wiring | Corroded connectors | Intermittent operation of components |

| Connections | Damaged insulation | Burning smell |

| Blown Fuses | Circuit overload | Loss of specific function(s) |

| Short circuit | Fuse repeatedly blows | |

| Grounding Issues | Poor connection | Erratic behavior |

| Insufficient grounding | Failure of electrical components |

Understanding these common issues and their potential causes can help technicians identify the root cause more efficiently. In the subsequent section, we will explore important safety measures that must be taken when working with electrical systems to ensure personal well-being and equipment protection.

Troubleshooting and Diagnosing Electrical Problems

Section H2: Troubleshooting and Diagnosing Electrical Problems

Imagine this scenario: You’re driving down the road on a hot summer day when suddenly, your air conditioning stops working. Frustrated, you pull over to diagnose what could be causing the issue. Welcome to the world of troubleshooting and diagnosing electrical problems in automotive and industrial systems. This section will guide you through the process of identifying and resolving common electrical issues.

To begin with, it is essential to understand some key signs that indicate potential electrical problems:

- Intermittent power loss: If certain components or systems in your vehicle or machinery experience sporadic power loss or flickering lights, there may be an underlying electrical problem.

- Fuse failures: Frequent blown fuses can suggest excessive current flow due to short circuits or other faults within the system.

- Non-functional components: When specific parts fail to operate as expected, such as malfunctioning headlights or unresponsive control panels, it often points towards electrical issues.

- Strange noises or burning smells: Unusual sounds like buzzing or crackling, along with unpleasant odors resembling burnt plastic or wires, should not be ignored as they can indicate electrical troubles.

Once these warning signs are identified, follow these steps for effective troubleshooting and diagnosis:

| Steps | Description |

|---|---|

| 1 | Begin by inspecting all visible wiring connections for any loose, corroded, or damaged connectors. |

| 2 | Use a multimeter to test voltage levels at different points within the circuit to identify irregularities in power supply. |

| 3 | Perform continuity tests across switches and relays to ensure proper functionality and rule out faulty components. |

| 4 | If necessary, consult diagnostic charts provided by manufacturers or seek professional assistance from certified technicians specializing in electrical repairs. |

By following these steps diligently, you can increase your chances of detecting and resolving electrical problems efficiently, saving both time and money. Remember, troubleshooting electrical systems requires patience and careful attention to detail.

Transitioning into the subsequent section on “Maintenance Tips for Ensuring Proper Functioning of Electrical Systems,” it is important to understand that while troubleshooting helps identify and resolve issues, regular maintenance plays a crucial role in preventing such problems from arising in the first place. By implementing proper care and preventive measures, you can ensure the longevity and optimal performance of your electrical systems.

Maintenance Tips for Ensuring Proper Functioning of Electrical Systems

Section H2: Troubleshooting and Diagnosing Electrical Problems

Building upon our understanding of troubleshooting and diagnosing electrical problems in automobiles and industrial systems, we now turn our attention towards essential maintenance tips for ensuring the proper functioning of these complex electrical systems. By implementing regular maintenance practices, individuals can significantly reduce the likelihood of encountering costly breakdowns or failures that may disrupt their daily operations. In this section, we will explore key strategies to keep electrical systems running smoothly, using practical examples and expert recommendations.

Example:

To better understand the significance of effective maintenance practices, let us consider a hypothetical scenario involving an automobile manufacturer. Imagine a car assembly line where various components are assembled with precision and efficiency. However, due to neglected maintenance on the electrical system, there is a sudden power failure. This leads to halted production, resulting in significant financial losses and delays. Such scenarios highlight the importance of regularly maintaining electrical systems to avoid potential disruptions.

Effective maintenance practices encompass several aspects that contribute to the overall reliability and longevity of electrical systems. Consider the following key strategies:

- Regular inspections: Conduct routine visual inspections of wires, connectors, switches, circuit breakers, and other components to identify any signs of wear or damage.

- Cleanliness: Keep electrical components clean by removing dust, dirt, and debris regularly as they can hamper performance and cause overheating.

- Tight connections: Ensure all connections within the system are tight and secure as loose connections can lead to voltage drops or intermittent faults.

- Lubrication: Apply appropriate lubricants to moving parts such as switches or relays to prevent friction-related issues.

Table – Importance of Maintenance Practices:

| Maintenance Practice | Benefit |

|---|---|

| Regular Inspections | Early identification of potential issues |

| Cleanliness | Improved performance and reduced risk |

| Tight Connections | Prevent voltage drops and intermittent faults |

| Lubrication | Minimize friction-related problems |

By implementing these maintenance practices, individuals can enhance the reliability and efficiency of electrical systems in automobiles and industrial settings. This proactive approach not only minimizes unexpected downtime but also extends the lifespan of critical components. Regular inspections, cleanliness, tight connections, and lubrication are simple yet effective strategies that contribute to the seamless functioning of electrical systems.

Through this comprehensive guide, we have explored troubleshooting techniques as well as essential maintenance tips for electrical systems in automobiles and industrial environments. By understanding common issues and adopting preventive measures, individuals can navigate potential challenges with confidence while ensuring optimal performance from their electrical systems. With continued advancements in technology, staying updated on best practices is crucial for efficient operations.

Comments are closed.